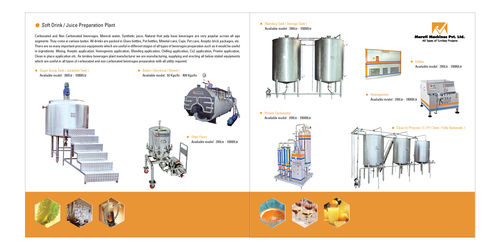

CSD plant

400000 INR/Plant

Product Details:

- Model No CSD-XXX Series (As per requirement)

- Frequency 50-60 Hz

- Plastic Processed PET, Plastic Bottles

- Efficiency (%) More than 95%

- Driven Type Motor Driven / Electric

- Accessories CO2 Pressure Regulator, Syrup Tanks, Carbonator, Filler Head, Conveyor System

- Usage & Applications Manufacturing of carbonated drinks, sparkling water, soft drinks

- Click to view more

X

CSD plant Price And Quantity

- 01 Plant

- 400000 INR/Plant

- Continuous

- 200ml to 2 Liters

- Adjustable Syrup to Water Ratio

- Below 75 dB

- Depends on plant size and capacity, typically 1-2 liters/liter CSD

- 6-8 bar

- Automatic CIP (Clean-In-Place) system integrated

- Counter Pressure Filling for precise carbonation

- AISI 304/316 Food Grade Stainless Steel

CSD plant Product Specifications

- Matt/Glossy as per requirement

- Stainless Steel (SS 304/316)

- Variable as per process needs

- 2C 10C (Chilling Section)

- Up to 5000 liters/hour

- Customized/As per plant configuration

- 3-15 HP (based on plant size)

- 2000-36000 bottles/hour (depending on configuration)

- Optimized for Energy Efficiency

- Approx. 3500-8000 kg

- On-Site Installation with Training Provided

- Fully Automatic

- Electric

- Sturdy design, Easy Installation, Low Maintenance, High Output, Hygienic Processing

- Automatic

- Beverage Processing Plant

- PLC Based

- 5-20 kW (Depending on Capacity)

- Motor Driven / Electric

- Silver (Stainless Steel Finish)

- Manufacturing of carbonated drinks, sparkling water, soft drinks

- CO2 Pressure Regulator, Syrup Tanks, Carbonator, Filler Head, Conveyor System

- 220V/380V/415V

- PET, Plastic Bottles

- More than 95%

- CSD Plant (Carbonated Soft Drink Plant)

- CSD-XXX Series (As per requirement)

- Yes

- 50-60 Hz

- Continuous

- 200ml to 2 Liters

- Adjustable Syrup to Water Ratio

- Below 75 dB

- Depends on plant size and capacity, typically 1-2 liters/liter CSD

- 6-8 bar

- Automatic CIP (Clean-In-Place) system integrated

- Counter Pressure Filling for precise carbonation

- AISI 304/316 Food Grade Stainless Steel

CSD plant Trade Information

- mundra

- 10 Plant Per Month

- 3 Months

- Contact us for information regarding our sample policy

- wooden box

- Asia, Africa

- All India

- ISI , ISO

Product Description

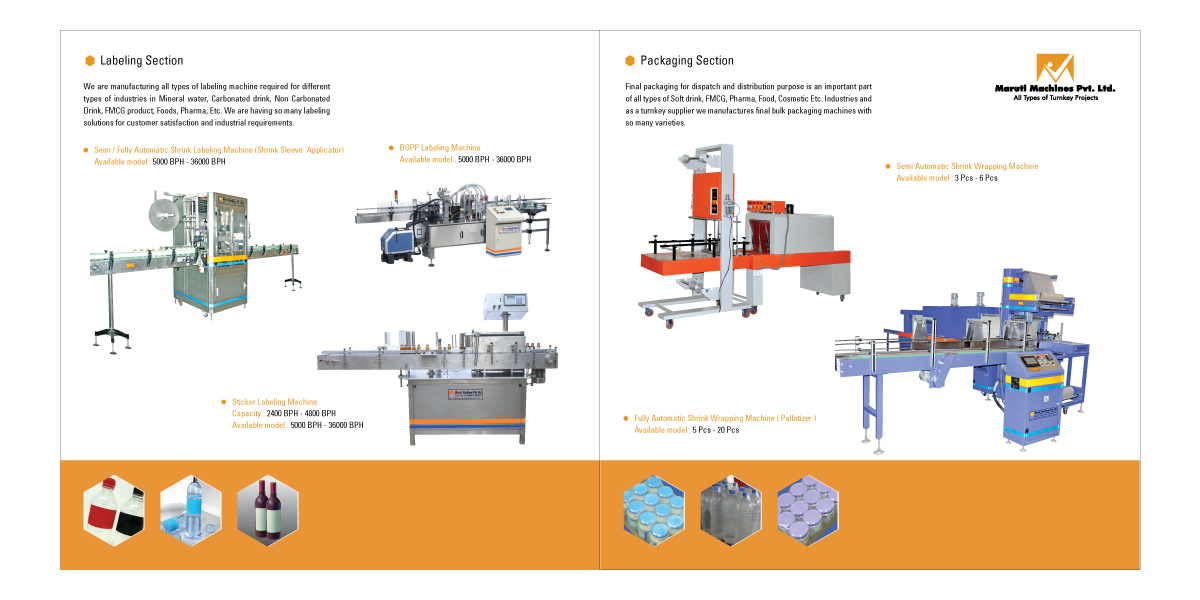

Tin / Pet Can Rinse Filling And Seaming Machine For Carbonated Drink, Aerated Drink, Carbonated Bear, Alcoholic Drink, ETC.

This is high standard advance Based online Rinsing,rotary counter pressurefilling and seaming Machine with In feed conveyer and Exit conveyor. This machine mainly used for washing, filling and Seaming of Aerated Drink such as carbonated soft drink, carbonated bear, carbonated wine, energy drink, sparkling drink and so on . The Machine design is shorten the time for the packaging of TIN/PET CAN, and reduce outside contamination and increased thesanitation conditionthroughout the machine operation is economical too.

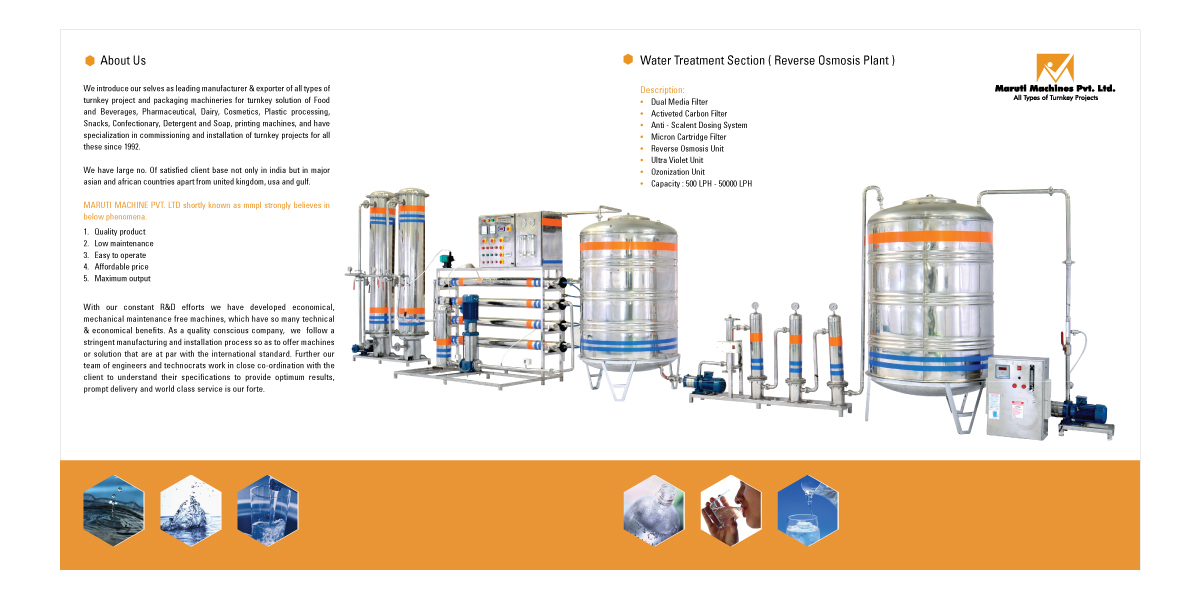

Advanced Cleaning with Automatic CIP System

The integrated automatic Clean-In-Place (CIP) system streamlines cleaning and sanitization processes, minimizing downtime and ensuring consistent hygiene. Use of food-grade AISI 304/316 stainless steel further prevents contamination and supports easy maintenance, extending the plants lifespan while complying with industry safety standards.

Precision Filling and Mixing Technology

With adjustable syrup to water ratios and counter pressure filling, the plant achieves precise carbonation and taste. This facilitates customizable beverage recipes and reliable product quality across different bottle sizes, ranging from compact 200ml bottles to large 2-liter containers, supporting diverse market demands.

Flexible, High-Efficiency Operation

The CSD plant offers fully automatic, PLC-driven control, optimized for energy efficiency and continuous operation. Capacity options up to 5000 liters/hour and production speeds up to 36,000 bottles/hour suit various business scales. Its robust construction and advanced accessories ensure high output with over 95% operational efficiency.

FAQs of CSD plant:

Q: How does the automatic CIP system enhance cleaning and maintenance efficiency in the CSD plant?

A: The automatic Clean-In-Place (CIP) system cleans and sanitizes internal surfaces without disassembly, minimizing downtime and labor costs. This ensures consistent hygiene standards, faster maintenance cycles, and reliable product quality, making the plant suitable for food-grade beverage production.Q: What are the material grades used in the CSD plant, and why are they important?

A: The plant uses AISI 304/316 food grade stainless steel, which is corrosion-resistant and easy to clean. These materials help maintain hygiene, prevent contamination, and provide durability for continuous production environments typical of beverage processing industries.Q: When should the syrup-to-water mixing ratio be adjusted during operation?

A: Adjustments to the syrup-to-water ratio can be made during batch set-up or when changing beverage recipes. The systems computerized, PLC-based controls allow operators to tweak ratios as needed to achieve desired flavor profiles and ensure consistent product quality.Q: Where can the CSD plant be installed, and what are the installation guidelines?

A: The CSD plant is designed for installation at beverage production facilities. On-site installation is provided with training, ensuring correct assembly and operation tailored to the plants customized configuration and local power requirements (220V/380V/415V).Q: What is the process for filling bottles using counter pressure technology?

A: Counter pressure filling introduces carbonated beverages into bottles at matched pressure, preserving carbonation and preventing foam overflow. This process delivers precise fills for bottles ranging from 200ml to 2 liters, supporting a variety of packaging formats and beverage types.Q: How does the CSD plant optimize energy consumption and support efficient operation?

A: The plants automated controls and energy-efficient drive systems regulate power usage based on production capacity. With motor power ranging from 3-15 HP and overall power consumption between 5-20 kW, it supports high-output production while minimizing energy costs and maintaining efficiency above 95%.Q: What are the key benefits of using an automated, PLC-controlled CSD plant in beverage manufacturing?

A: Key benefits include high production output, customizable recipes, precise carbonation, hygienic processing, and low maintenance. Automated control via PLC not only streamlines operation but also ensures consistent results, safety, and improved overall efficiency for beverage producers.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese