Glass Bottle Filling Machine

Product Details:

- Motor Power 2 HP

- Efficiency (%) 98%

- Production Capacity 2000-4000 Bottles Per Hour

- Model No GBFM-2024

- Installation Guideline On-site Installation Support Provided

- Frequency 50 Hz

- Temperature Range 5C - 40C operating environment

- Click to view more

Glass Bottle Filling Machine Price And Quantity

- 01 Unit

- 1685000 INR/Unit

Glass Bottle Filling Machine Product Specifications

- Automatic

- 2.5 kW/hr

- 650 kg

- Stainless Steel, Food Grade Components

- Silver

- Electric

- Yes

- Beverage, Juice, Water, Liquor and Pharmaceutical Bottle Filling

- Glass Bottle Filling Machine

- 2.5 kW

- Electric

- 1900 mm x 1100 mm x 1650 mm

- Automatic

- Adjustable

- 100 ml - 1000 ml per bottle (Configurable)

- 2000-4000 Bottles Per Hour

- 98%

- 2 HP

- Polished

- Filling & Capping

- High Filling Accuracy, Low Maintenance, Anti-Drip Nozzles, Multiple Bottle Sizes Supported

- 220V/380V

- 5C - 40C operating environment

- Programmable Logic Controller (PLC)

- Bottle Infeed Conveyor, Outfeed Conveyor, Nozzle Set

- On-site Installation Support Provided

- GBFM-2024

- 50 Hz

Glass Bottle Filling Machine Trade Information

- MUNDRA PORT

- Cash in Advance (CID), Cheque, Cash Advance (CA)

- 01 Unit Per Month

- 01 Months

- Contact us for information regarding our sample policy

- WOODEN BOX

- Africa, Asia

- All India

- ISO

Product Description

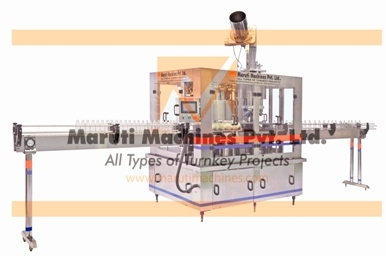

Glass Bottle Filling Machine

- Digital Gravity Filling And Crowning Machine With Cap Feeder, In-feed And Exit Conveyor For Pet Bottle.

- Machine Output Capacity: - Start From 20 bottle /min. Filling Capacity To 160 Bottle/min.

Specification

|

Application |

Beverages, Water and Wine. Packaging |

|

Operation |

Touch Screen |

|

Voltage |

380 V |

|

Filing Type |

bottle filler |

|

Model No. |

MMPLRFC |

|

Brand |

Maruti Machine |

|

Packaging Type |

Bottle |

|

Type |

Filling Machine |

|

Capacity |

30 BPM |

|

Automatic Grade |

Automatic |

|

Automation Grade |

Automatic |

|

Driven Type |

Electric |

|

Packaging Material |

glass bottle |

|

I deal in |

New Only |

|

Machine Type |

Automatic |

|

Type of Beverage |

Tea,Coffee,Cold Drink |

|

Usage/Application |

Customize |

We are dedicatedly engaged in providing awide series of Glass Bottle Filling Machine. It is manufactured under the supervision of adept experts and cutting edge tools. This machine is an automatic and multi-functional machine to use in a reliable manner. It is simple to set up and maintain. Glass Bottle Filling Machine promotes higher production rates and automatically fills or seals the bottles according to the need. It is mostly useful in water, packaging and beverages industries.

Versatile Filling for Multiple Bottle Sizes

With its adjustable digital control for fill volume and support for a range of bottle diameters and heights, the GBFM-2024 makes it simple to process a variety of glass bottles without complex manual changes. This flexibility is ideal for manufacturers needing to switch between different product lines or bottle specifications quickly and efficiently.

Precision Engineering & Hygienic Operation

Engineered with food-grade stainless steel and equipped with a Clean-In-Place (CIP) system, this machine ensures both product safety and operator convenience. An anti-drip nozzle setup further maintains cleanliness by preventing spillage, while the touch screen HMI and PLC control provide precise, user-friendly adjustments and monitoring.

Safety and Reliability Guaranteed

The GBFM-2024s comprehensive safety features include emergency stop, overload protection, and a robust, electric-driven design. It operates quietly (<75 dB) and maintains a consistent performance with adjustable speed and high efficiency, making it suitable for diverse beverage and pharmaceutical applications.

FAQs of Glass Bottle Filling Machine:

Q: How does the volumetric filling principle enhance the accuracy of the Glass Bottle Filling Machine?

A: The volumetric filling system uses precise measurements to ensure each bottle receives an accurate quantity of product, which is digitally adjustable between 100 ml and 1000 ml per bottle. This method minimizes product waste and ensures consistency across batches.Q: What types and sizes of bottles are compatible with this filling machine?

A: The GBFM-2024 is specifically designed for glass bottles with diameters ranging from 30 mm to 100 mm and heights from 100 mm to 320 mm. It supports various shapes and capacities within these physical parameters.Q: When should the cleaning-in-place (CIP) system be used, and how does it work?

A: You should utilize the CIP system regularly, especially when switching products or during routine maintenance. The CIP system allows internal cleaning of machine components without disassembly, ensuring hygiene and reducing downtime.Q: Where can the machine be installed and what support is provided?

A: The Glass Bottle Filling Machine is suitable for industrial settings such as beverage, water, juice, liquor, and pharmaceutical plants. On-site installation support is provided to ensure correct setup and optimal performance.Q: What is the typical process for operating the Glass Bottle Filling Machine?

A: Operators place or feed bottles onto the provided infeed conveyor. The PLC and touch screen HMI allow configuration of fill settings and speed. The machine then automatically fills bottles via 8 nozzles and transfers them to the outfeed conveyor after capping.Q: Why is the machine efficient for high-volume production?

A: With a production capacity of up to 4000 bottles per hour, automatic operation, 98% efficiency, adjustable speed, and minimal maintenance requirements, the GBFM-2024 is ideal for high-throughput environments.Q: What are the main benefits of using stainless steel and food-grade components in this machine?

A: Using stainless steel and food-grade materials ensures product safety, resists corrosion, simplifies cleaning, and complies with strict food and pharmaceutical industry standards, reducing contamination risks.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese